Nice work, thanks for the diagrams.

- 3 Posts

- 19 Comments

2·1 year ago

2·1 year agoMouser/farnell. Coilcraft inductors are quite expensive yeah, but often there are lower priced equivalents, or when possible a larger size/cheaper model can be used

3·1 year ago

3·1 year agoI already know someone who could machine parts for me, so yeah I should start designing something.

1·1 year ago

1·1 year agoHaha thank you, I wish I was able to make my hosts.

2·1 year ago

2·1 year ago“oh yeah, I made an aux board too” 😂

Naturally 😁

And thanks!

I see, looking at pictures the tube is screwed down against the pill, I guess the pill must have some kind of hard stop when screwed down so that it doesn’t change position, as opposed to say and S2+ where the pill compresses the oring thus doesn’t have a hard stop.

Unrelated to OP but commenting here since it’s about reddit. Did you notice that mentioning Lemmy on reddit gets your comment shadow removed ? here’s two of mine I just noticed thanks to this AMA about Revedit

I’m curious how the head and tube perfectly align for the one on the right (Citadel ?), I’ve seen it before and thought it looks really great. Although I wish these nice lights were more compact, they look fairly large for the size of the cell.

2·1 year ago

2·1 year agoThanks.

That plating process looks like a real pain, any benefits over using a copper pcb to begin with?

None except cost. When I started this project a DTP MCPCB would have cost in the 300-400$, but since the start of 2023 JLCPCB is offering a DTP MCPCB service for 50$ base price which is much more reasonable, for a large MCPCB like this I would use this service now. For a small (single/few LEDs) one off MCPCB I might still go with the plating route since the alu MCPCB is so cheap.

3·1 year ago

3·1 year agoThanks

although I think these drivers could become very expensive and once the manufacturers start substituting components it’s efficiency could decrease.

The buck ICs I used are actually not very costly, the inductors are a bit pricey but since there is quite a bit of free space on the board, (and unused stuff for low side sensing because I made it both high/low side sensing) larger cheaper Chinese ones with similar specs could be used and the performance would be unaffected.

Generally that’s what I would do if contracted for a driver, for example I made my BST21 one sided and 0603 min size for easier self assembly, due to that I used a 70x0 inductor size (~7.5×7.5mm, variable height), which if it was Chinese branded would not have satisfactory specs.

If asked to design a similar driver I would use a larger 1040 inductor (10×11mm×4mm, common size used in Convoy drivers) that are even a bit better than the Bourns/Coilcraft 70x0 but cheaper, the driver would need to be double sided but produced in large quantities this doens’t have a high cost. The converter IC can’t he be substituted, the only other power component would be the RPP PFET but there are a few pretty good chinese ones like the one used in Noctigon boost drivers.

Unfortunately Neopixels consume too much power, about 1mA quiescent current each, also min Vin is 3.75V according to the datasheet.

The other day I found this small RGB controller, 200uA quiescent current (LEDs off), 300uA LEDs ON, which is much better especially with only one controller for all the aux LEDs.

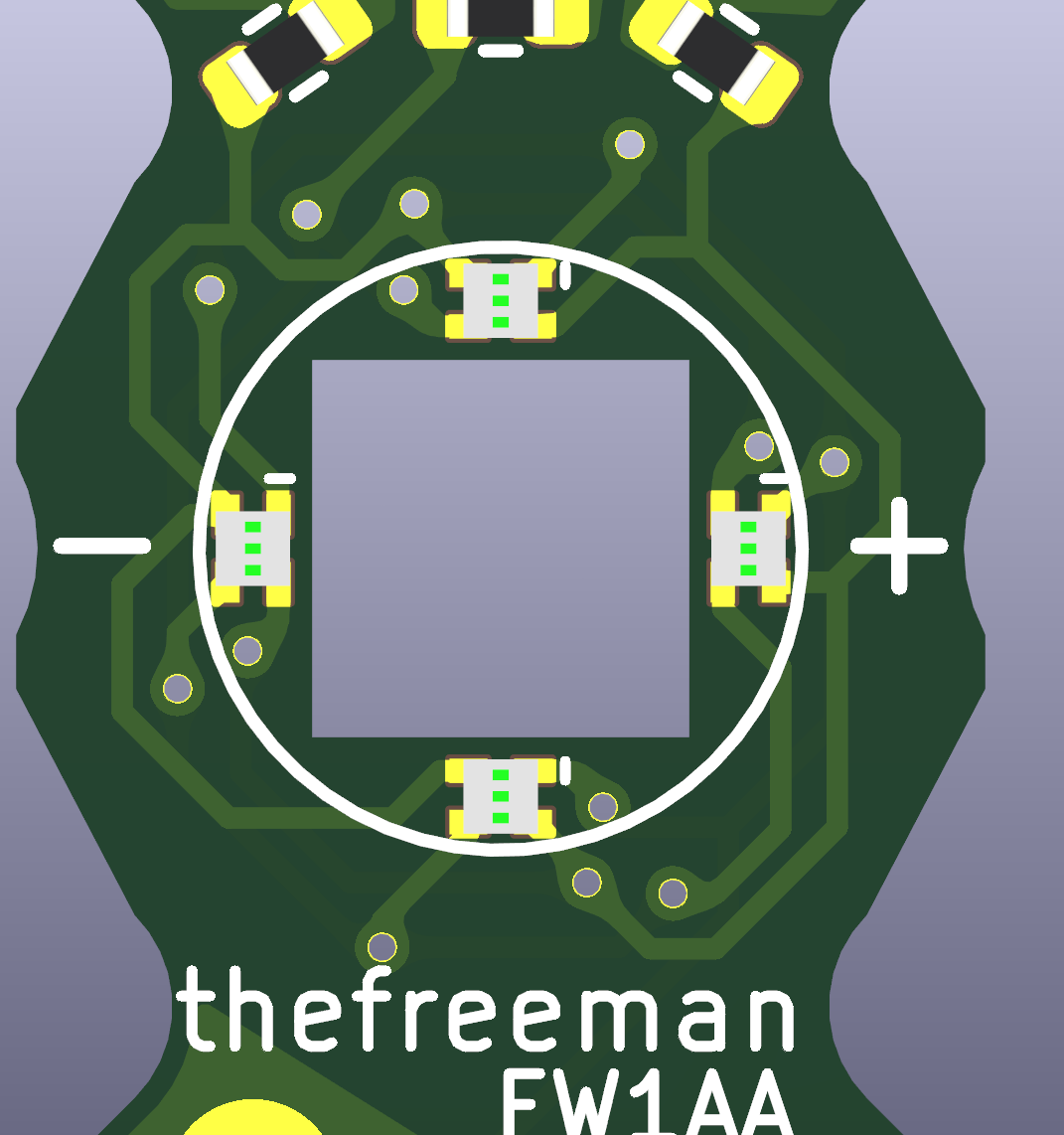

The small one dubbed BST15 is a 15mm component clearance/17mm total diameter boost driver, rated for ~40W (6A~6.5V, 3A~13V), with HDR (low moonlight), it’s compatible with e-switch (Anduril) and Mike_C’s OTSM implementation for clicky switch, I made it (with his blessings) so that it is easier to build than his version and added reverse polarity protection , my first version had some issues at high current, at the time I didn’t do too much troubleshooting and left it aside, recently I made an updated version, which is the one I just assembled and it works well. The next step is assembling a couple more to send to Mike so that he can finish his firmware, then I’ll share the PCB/BOM for people to assemble it themsleves.

The big one is also a boost driver, 1S input, I’ll post more detail once I have finished testing it, I did some partial efficiency test already but I don’t have a power source powerfull enough to test it at max current 😅.

It’s for a rather popular light so it shouldn’t be too hard guess which.

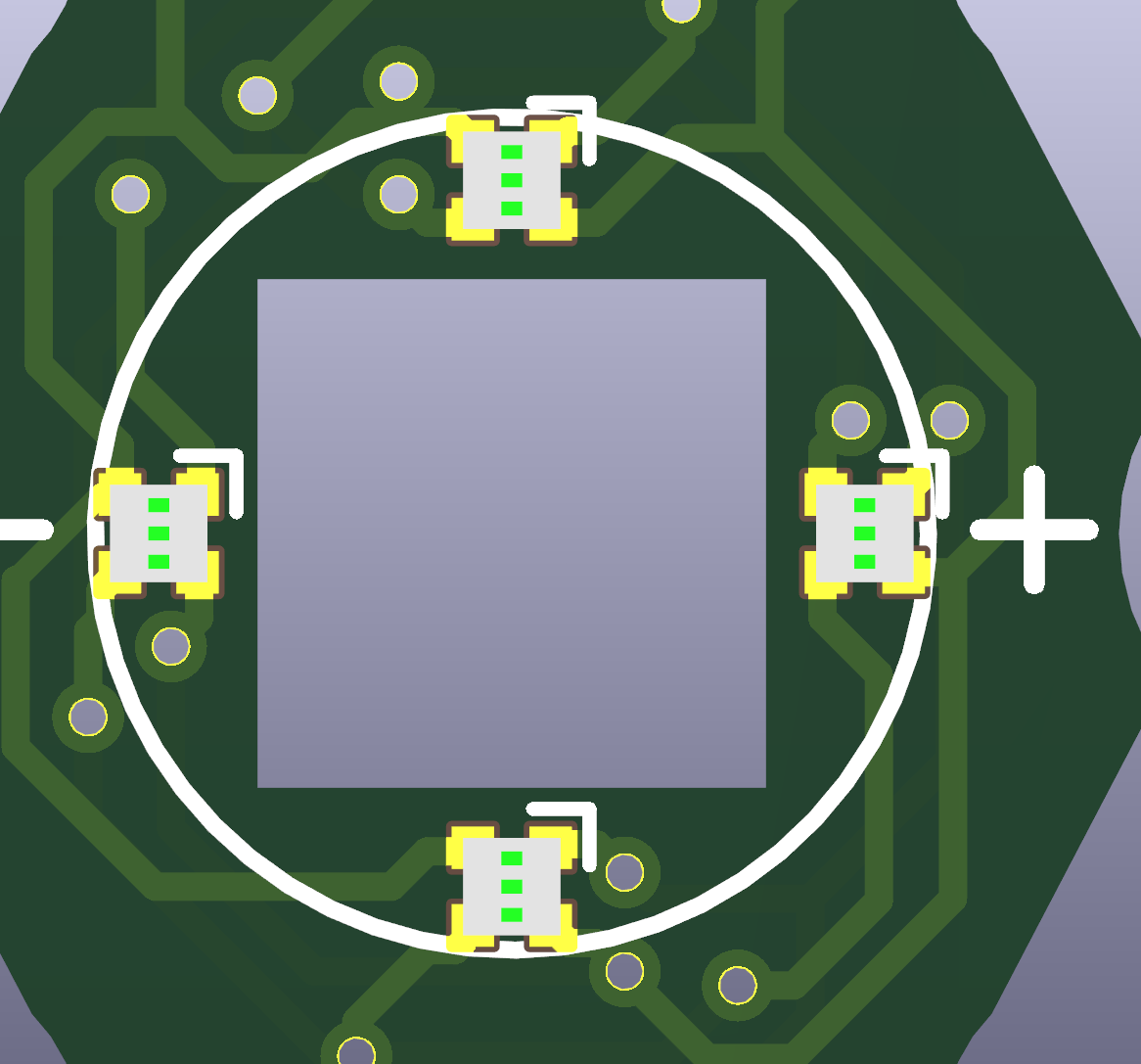

Circle is 5.6mm :

I don’t remember exactly but I probably chose the 0.69mm ones because they cost half as much. The 0.04mm difference being pretty negligible. I also have the 0.9mm ones that I use when the classic 0606 are just a bit too big, they are easier to handle.

What’s the diameter of the opening ?

Edit :

If I can eventually find one that is.

Oh you don’t have one, measuring from a picture I get 5.9mm, if that’s right then it will be very close.

I can try making a version with the LEDs closer to the 3535 cutout.

if you have an emisar light and can disassemble it, then you can try soldering an airwire from the sense resistor to the button LED pad (sacrificing it for that) or a free ADC pin, but that’s more difficult. If that cause problems with the current regulation, add a 10k resistor or the likes.

with a linear driver Iout=Iin so it’s simple, with a boost driver Iin=(Vout x Iout)/(Vin x efficiency), thankfully Vin is already bein measured, Vout and efficiency need to be guesstimated.